Bitumen Emulsion Definition, Types and Grade

Bitumen Emulsion

Bitumen emulsion is a liquefied form of bitumen with low viscosity, making it easier to handle and apply.

By dispersing bitumen in water and adding an emulsifier, regular bitumen becomes a liquid that can be used in a wide range of applications, such as road maintenance, waterproofing, spraying, and other construction tasks.

Bitumen emulsions offer several practical benefits: they are easier to transport, store, and apply at lower temperatures, eliminating the need to heat the bitumen before use. Using cold application methods also reduces energy consumption and supports more environmentally friendly construction practices.

Composition of Bitumen Emulsion

A bitumen emulsion is primarily composed of bitumen and water. Since oil and water naturally separate, an emulsifier is added to stabilize the mixture.

Typically, bitumen makes up 55–65% of the emulsion, water accounts for 35–45%, and emulsifiers constitute up to 0.5% of the total weight. Emulsifiers reduce the surface tension between oil and water, allowing them to mix more effectively.

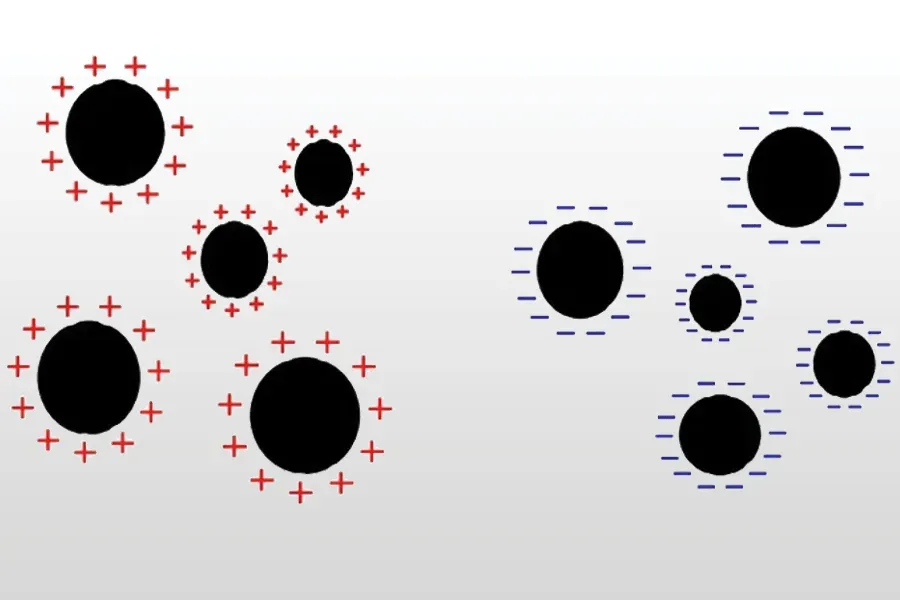

Emulsifiers also carry an electrical charge, which determines whether the emulsion is cationic or anionic. Cationic emulsifiers create a positively charged layer around bitumen droplets, preventing them from coalescing and improving the stability of the emulsion.

The type of emulsifier used influences which surfaces or aggregates the emulsion works best with. For instance, some aggregates mix more effectively with anionic emulsions, while others are better suited for cationic emulsions.

How is Bitumen Emulsion Manufactured?

Bitumen emulsion is typically produced using a colloid mill, which blends bitumen with water and an emulsifier. During this process, the bitumen is broken down into very small droplets that can easily remain suspended in water.

The addition of emulsifiers helps the bitumen droplets interact with water more effectively, while water droplets surround the tiny bitumen particles, ensuring the emulsion remains stable.

Several factors are carefully controlled during production, including droplet size, chemical additives, and the temperature of the components. This precise control results in a bitumen emulsion with a consistent structure, suitable for a variety of construction and maintenance applications.

Different Types of Bitumen Emulsion

Bitumen emulsions are classified based on two main factors:

- Electrostatic charge of particles:

- Anionic (A): particles carry a negative charge.

- Cationic (C): particles carry a positive charge.

- Breaking or setting time:

Setting refers to the process where water evaporates, allowing bitumen to adhere to aggregates and harden. The setting time determines the emulsion type:

- Rapid setting (RS): sets quickly upon contact with aggregates; commonly used for surface treatments like chip seals.

- Medium setting (MS): sets moderately; suitable for premixed aggregates, especially open-graded mixes.

- Slow setting (SS): sets slowly; ideal for mixing with high surface area aggregates, dense bases, slurry seals, and asphalt recycling.

Surface temperature also affects setting time—higher temperatures accelerate water evaporation. Both cationic and anionic emulsions follow this classification based on their reactivity rate.

| Bitumen Emulsion Types | ||

|---|---|---|

| Cationic Emulsion | Anionic Emulsion | |

| Rapid setting type (RS) | CRS-1 CRS-2 CRS-1h K1-60 K1-40 K1-70 | RS-1 RS-2 |

| Medium setting type (MS) | CMS-1 CMS-2 CMS-2h K2 K3 | MS-1 MS-2 MS-2h HFMS-1 HFMS-2 HFMS-2h HFMS-2S |

| Slow setting type (SS) | CSS-1 CSS-1h Modified CSS-1h | SS-1 SS-1h Modified SS-1h |

Understanding Bitumen Emulsion Prefixes and Suffixes

Bitumen emulsions are often described using numbers and letters that indicate their key properties.

- Numbers 1 and 2 refer to the viscosity of the emulsion: 1 indicates lower viscosity, while 2 indicates higher viscosity.

- The letter h represents a harder base bitumen (lower penetration grade, e.g., 30/40), whereas s denotes a softer base bitumen (higher penetration grade, e.g., 80/100), suitable for mixing with sand or fine aggregates.

- The HF prefix indicates that a polymer-based emulsifying agent has been added, creating a gel structure in the bitumen residue.

This gel structure allows for a thicker coating on aggregate particles, improving the surface’s resistance to oxidation and enhancing durability over time.

Bitumen Emulsion Application

In the early 20th century, bitumen emulsions were used mainly for spray applications, but nowadays they are also used for mixing and spraying in road construction and road maintenance.

This type of bitumen is used in various methods of road construction including tack coats, chip seals, slurry seals and micro surfacing.

More details about bitumen emulsion application are presented in the following.

- Tack Coat:

Bitumen emulsion especially CRS-1 and CRS-2 are the best choice for tack coats between layers of asphalt pavement.

They can be used to heavily improve the strength and fatigue life of asphalt pavement at a very low cost and it’s better to know that the use of cut back bitumen has been avoided.

For running tack coats, the best temperature is 10 to 15 degrees Celsius.

- Chip Seals:

It is possible to use bitumen emulsion to renovate and waterproof old roads.

Chip seals are one of the most cost-effective methods of pavement preservation, since they protect underlying pavement from oxidation and aging.

Generally speaking, chip seals are typically used on rural roads carrying lower traffic volumes.

- Slurry Seals:

In order to give a uniform texture to roads, engineers use slurry seals.

This mixture of bitumen emulsion, aggregates and mineral fillers is sprayed on the pavement to seal it and make the surface weather-resistant.

Slurry sealing is also used in the maintenance of asphalt pavements and it helps to reduce road surface damage due to bitumen oxidation, but cannot increase its structural strength.

- Micro Surfacing:

Micro surface is another form of slurry in road construction, which is composed of polymer modified bitumen emulsion.

The existence of dense-graded aggregates in this mixture makes it stronger and more durable than a slurry seal.

A specialized machine is used to apply the mixture on existing pavements, which carries all components and mixes them on-site. The mixture is then spread onto the road surface.

Advantages of Bitumen Emulsion to Cut Back

These bitumen emulsions are used in road constructions as a substitute for cut back bitumen and perform all the functions that cut back bitumen can perform.

- Bitumen emulsions are more economical than cutback bitumens. Because in most cases bitumen emulsions contain 60% bitumen and 40% water, while cut back bitumen contain 70% bitumen and 30% petroleum solvents such as kerosene, naphtha, diesel oil, etc. It is obvious that 40% water costs lower than 30% petroleum solvent.

- In comparison with cut back bitumen, it is not flammable.

- As emulsion mixes do not require hot mixing, the strength properties of bitumen are preserved. Cold mixing or only slightly heating of the emulsion ingredients is usually done for the construction of the pavement.

- Emulsions can be applied even when it’s raining in wet weather.

- Emulsions with lower viscosities are more spreadable and allow for better bitumen coating on aggregate surfaces.

- There is no waste in laying and storing.

- Compared to all building materials, it requires little or no energy to heat.

Disadvantages of Bitumen Emulsion

Since bitumen emulsions are a type of soluble bitumen, they can have disadvantages based on the solvent.

If it is soap or water based, it has no disadvantages, only its price is higher, when the mixture is poured on the ground, the water evaporates and the bitumen sticks as a binder.

But if it is based on gasoline solvent, when it evaporates, toxic substances such as sulfur remain in the environment, which causes diseases such as cancer.

Sometimes, in a long-term storage condition or when temperature changes are large, it may become two-phase and frangible.

Bitumen Emulsion Standard

In the US, two central institutions have defined and standardized bitumen emulsion classifications:

- The American Association of State Highway and Transportation Officials (AASHTO)

- The American Society for Testing and Materials (ASTM)

There are societies and institutions throughout the world that have standardized how bitumen emulsions are classified, identified, and tested.

These foreign institutions look up to AASHTO and ASTM and adapt their findings to the local context.

For example, in Brazil, the Brazilian Association of Technical Standards is the organization that is responsible for standardizing testing and classifications for all types of materials. Like emulsions, they adapt quality standards set by the American institutions to the reality of Brazil.

Sample of several bitumen emulsion standards are as follow:

- American standards :

- Anionic Emulsion: ASTM D977, AASHTO M140

- Cationic Emulsion: ASTM D2397, AASHTO M208

- En 12597

- IS 3117 (2004)

- BSI 434-2 (2006)

Leave a Reply